| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Kiande

Model Number : KD-YYJ-40(50)T

Certification : ISO9001

Place of Origin : China

MOQ : 1 set

Price : customized

Payment Terms : T/T, L/C

Supply Ability : 10sets/ month

Delivery Time : 30 working days

Packaging Details : plywood case

Name : Busbar Fabrication Machine

Pressure : 40T or 50T, Max. 80T

Feature : One Time Molding

Workplace Size : L450mm*W340mm

Bending thickness : 3-10mm

Air Source : 0.6MPa

Bending Power Type : Hydraulic and pneumatic hybrid

Die : Fast die change

Equipment Dimension : L680mm* W580mm* H2600mm

Power : 220~230VAC 50~60Hz 80W

Other name : busbar punching machine

High Accuracy Hydraulic Compact Busbar Manufacturing Machine

Principle characteristics

The gas-liquid supercharger uses the high-pressure gas produced by the compressor to deliver the compressed gas to the solenoid valve through the pipeline. The solenoid valve is controlled by the foot switch to control the work and return of the cylinder to achieve the purpose of punching. The compressed air can be stored in the air storage tank and used at any time, so there is no energy waste of the motor when idling. Using the cylinder as the working part and the solenoid valve as the control element, the structure is simpler, the failure rate is low, the safety is high, the maintenance is simple, the maintenance cost is lower, and the production efficiency is high. The use of 220V power supply to control the solenoid valve is simple and convenient.

Function introduction

Digital bus bar Hydraulic Punching Machine is used to punch the two ends of busbar in one time to guarantee parallelism between busbar profile and conductor. This parallelism ensures the reliable connection between conductor and joint which can control joint temperature rising. Key point is that machine can adjust the rebound coefficient according to conductor’s material and width. Rebound coefficient varies by bending or different conductor width and this kind of adjustment can guarantee the parallelism.

Equipment data on digital copper bar punching machine

| No. | Parameters |

| Model | KD-YYJ-40(50)T |

| Bending Power Type | Hydraulic and pneumatic hybrid |

| Pressure | 40T or 50T, Max. 80T |

| Die | Fast die change |

| Workplace Size | L450mm*W340mm |

| Control Mode | Digital control |

| Air Source | 0.6MPa |

| Power | 220~230VAC 50~60Hz 80W |

| Equipment Dimension | L680mm* W580mm* H2600mm |

|

|

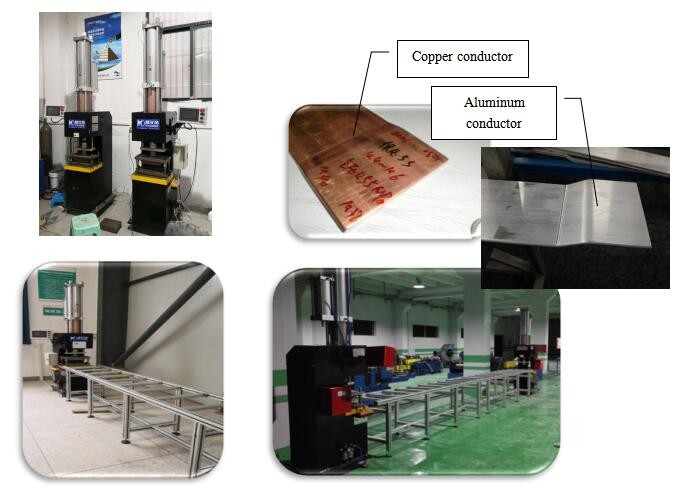

High Accuracy Hydraulic Compact Busbar Manufacturing Machine Images |